Research Projects

Here are five projects the GRTP team is currently working on.

Title : Bridging the gap between phytoremediation solutions on Growing energy crOps on contaminated LanDs and clean biofuel production

Project in partnership with 18 other partners as part of the EU/Canada HORIZON 2020 collaboration

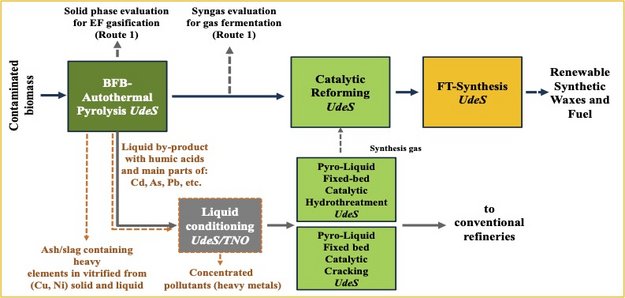

This project co-financed by FRQ/Quebec and FNFR/Canada uses thermochemical/thermocatalytic methods, such as pyrolysis and gasification of pure or contaminated agricultural biomasses with the aim of concentrating & recovering contaminants while producing bio-sourced energy and material. The specific objectives of this project are:

- Convert different biomasses contaminated through their use in phytoremediation using a new patent-pending autothermal pyrolysis technology into solid, liquid and gaseous products.

- Evaluate the distribution of contaminants (heavy metals) in the three product phases and optimize their capture/concentration in the residual solids from their pyrolytic treatment.

- Use liquid products as they are or after thermal or thermocatalytic pretreatment (cracking or reforming) for the production of carbon nanofilaments (CNF) in a patent-pending hybrid reactor (fluidized bed combined with a moving bed).

- Use gaseous products as such or reformed for:

- Also produce NFC

- Synthesize bio-sourced clean liquid fuels with new Fischer-Tropsch synthetic nanocatalysts in three-phase or two-phase reactors.

Researchers involved: N. Abatzoglou and I. E. Achouri

Total budget : € 2,999,950 + $ 600,000

Duration : 2021-2025

Towards a New Generation of Catalysts (M-UGSO) Based on UGSO Mining Residue

This project, co-financed by PRIMA Québec and RIO Tinto Fer et Titane, aims at the kg-lab scale-up of a process for the production of synthesis gas, a precursor of hydrogen, using a new patent pending steam and dry (CO2) reforming catalyst. In the said project, there are two specific sub-objectives:

- Demonstrate that the process is techno-economically and environmentally viable under conditions used in industry (high temperature and pressure).

- Demonstrate that the new catalyst can be produced according to industry standards and be competitive in the market both by its robustness and efficiency and by its greatly reduced cost due to the use of a metallurgical residue at negative cost.

Researcher involved: N. Abatzoglou

Total budget : $ 260,000

Duration : 2021-2023

GOLD – Bridging the gap between phytoremediation solutions on growing energy crops on contaminated lands and clean biofuel production, is a research and innovation action funded by the European Union Horizon 2020 and the government of Canada.

The Government of Quebec is investing an additional amount in the Horizon project to improve the infrastructure available in the GRTP.

Researchers involved: N. Abatzoglou and I. E. Achouri

Total budget: $ 200,000 / 2021-2025

Title: Valorization of wet organic residues by steam cracking and biomethanization

Biomass from residential waste is an important source, which would help address growing concerns such as waste management and climate change. To convert these feedstocks into valuable fuel, pre-treatments are required. Biomethanization then makes it possible to recover the organic fraction of residues from different sources (agricultural, commercial, industrial, municipal) and to produce biogas, composed mainly of methane and carbon dioxide.

The research and development efforts of the proposed project with the University of Sherbrooke constitute the last step before the commercialization of the pairing of steam cracking of wet organic matter as a pretreatment to biomethanation for the production of biofuels such as renewable natural gas.

Researchers involved: I. E. Achouri and N. Abatzoglou

Budget: $ 100,000 / 2022

Title : Conversion of waste polymers to carbon nanofilaments

This project, co-funded by PRIMA Quebec, CRSNK, KWI Polymers Solutions Inc and Soleno Inc., aims to prove the concept of recovering polymer waste into carbon nanofilaments (NFC) to be used as additives improving the specific properties of marketed polymers. This proof is done by modeling the development and construction of a kg-lab scale process unit based on the scaling up of two new patent pending thermo-catalytic reactor technologies: an autothermal pyrolyzer (ATP) and a catalytic carbon nanofilaments (CNF) production reactor combining a fluid bed and a moving bed inside the same vessel. Within the framework of this project, the specific objectives and the methodology are briefly presented below:

- Conditioning of polymeric waste.

- Model, design, build, operate and optimize the autothermal bubbling fluidized bed ATP reactor on the kg-lab scale (nominal treatment capacity of 5 kg/h).

- Model, design, build, operate and optimize the production reactor and the NFC separation and collection train at the kg-lab scale (nominal production capacity of 1 kg/h).

- Reforming of ATP products upstream of the NFC production reactor feed.

- Incorporation of NFCs into the matrix of recycled polymers via KWI’s technologies.

- Evaluation of reinforced polymers.

Researchers involved: N. Abatzoglou and I. E. Achouri

Duration : 2017-2022